Why don’t more 3D printer manufacturers create and market military product offerings?

For better or worse, it turns out that world’s militaries like to spend money – a lot of money. In 2022 alone, global military spending was at an all time high (for the 8th consecutive year) at over $2.2 Trillion, and you better believe that 3D printers made up a portion of that spending. Why?

3D printing as a technology provides the key benefit of on-demand manufacturing. Militaries operate loads of vehicles and equipment that require tools and maintenance – often in remote locations. Traditionally that means long supply chains and lots of spare parts, but with 3D printers, military personal can reduce their reliance on resupply convoys – storing part design files digitally, and print the parts as needed (also reducing physical inventory requirements). Combine that with the high-performing materials that are now available, and bam, you’ve got a nearly perfect product-market fit.

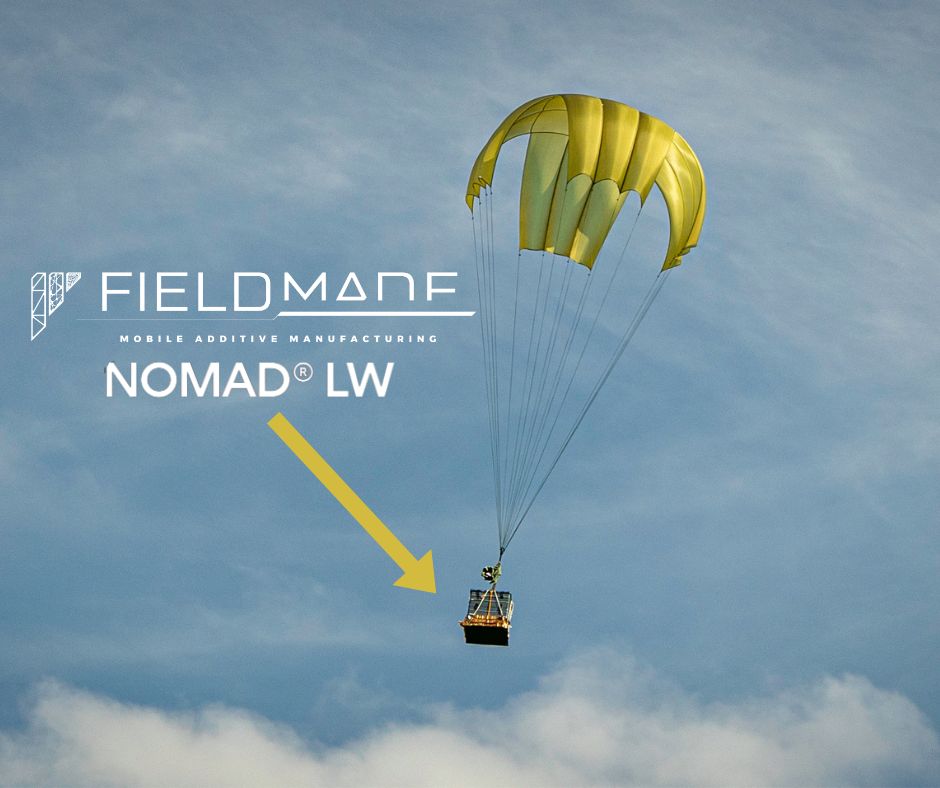

Dropping 3D Printers from Military Cargo Planes

Picture a military cargo plane swooping low near the front lines of a conflict, as it passes overhead you can make out the open ramp in the back. A parachute deploys and pulls a large crate into the air while multiple large chutes deploy. The crate slowly floats down the ground. What’s in the crate? On-demand manufacturing in a box – a field-ready 3D printer.

Fieldmade AS has found its niche in 3D printing for military applications. Since 2016 they’ve been developing deployable 3D printing lab containers, and in 2022 they partnered with Mark3D – a reseller of the popular Markforged 3D printers – to develop a smaller, more deployable 3D printer called the Nomad® LW. The Nomad LW is a small 3D printer based on the Markforged Mark Two™ architecture.

The Nomad LW is basically a desktop 3D printer packed into a rugged travel case, along with spare parts and enough filament to last 3 months. Like the Mark Two, Nomad LW is capable of 3D printing lightweight carbon fiber parts that have the strength and rigidity of metal. Fieldmade AS partnered with the British Armed Forces on the project and tested deployability from an Airbus A400M Atlas military transport aircraft.

Military-Focused 3D Printing Solutions

While Fieldmade AS seems to have initially lead the market with the rugged retrofitting and packaging with the Nomad LW, Markforged themselves have since crafted their own deployable solution – the X7™ Field Edition (FE). Much like the Nomad LW, the X7 FE ships in a rugged and deployable case (though it’s not clear if materials come with the package).

While the X7 FE 3D printer is pretty much just the standard X7 model, the included case and custom fit foam help to differentiate it from their standard B2B lineup and that’s important. There are dozens of 3D printing companies around the world, most of whom are vying for military contracts, but many of them have neglected military-specific productization or marketing which likely gives Markforged a leg up when bids come out. Case-in-point, the US Naval Sea Systems Command recently integrated an X7 FE aboard the USS New Hampshire – a Virginia Class nuclear powered attack submarine. Just… wow.

Another 3D printer manufacturer who is following the playbook of Markforged and Fieldmade is SPEE3D. While the Markforged’s field solutions are small enough to be airdropped and 3D prints exclusively polymers and composites, SPEE3D’s XSPEE3D is essentially a manufacturing cell within a 20 foot shipping container. Oh, and it prints in metal which is still the top dog when it comes to high-demand materials within the military.

Non-Military 3D Printers in the Military

While Markforged and SPEE3D have taken the next step to field-ready packages, other brands have found success earning military footholds with their standard 3D printer catalogs.

The Royal Netherlands Air Force streamlines aircraft repair by making custom parts with the Ultimaker S3 3D printer – as featured in one of UltiMaker’s case studies. The 3D printers are located at a military base in Woensdrecht and have produced tools for working on their Chinook, Apache, NH90, and F-16 aircraft to name a few.

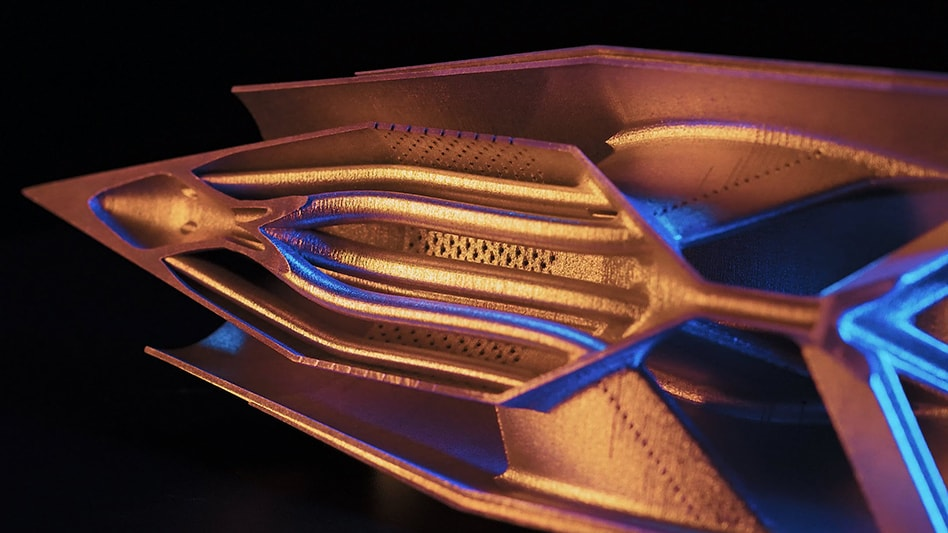

3D printing manufacturer Velo3D partnered with Lockheed Martin to produce some impressive ramjet engines for hypersonic aircraft (though it’s unclear if these have made their way to the field).

Both Markforged and Lulzbot (an unlikely combination to be sure) have made their way to US Marines Expeditionary Fighting Force stationed in Okinawa, Japan to be tested in deployable 3D printing labs within specialized shipping containers.

Meltio3D’s Meltio Engine CNC Integration Hybrid Manufacturing Solution – essentially a modular metal 3D printing platform integrated into a Haas TM-1 – was deployed aboard the USS Bataan – a WASP-class amphibious ship.

So why don’t we see more military segmented products?

There’s no doubt the market opportunity for military applications using 3D printers is massive but it might not be so easy for every 3D printing manufacturer, here’s why:

- Base products may require extensive modifications, certifications – not all companies have the resources to focus on this.

- Bids from countries like the US may require manufacturing done within national borders.

- Products may simply not hold up to the rigorous testing requirements of the armed forces.

- Winning contracts may require a different type of business development outside of the revenue team’s existing repertoire.

- Marketing may require a completely different brand segment than the core marketing team has time for.

Because of these reasons, some brands may choose to focus their efforts on more transparent public market segments.

So what do you think? Is it a worthwhile endeavor to devote resources to the military market segment? Based on some of the above products, I think it might actually be a lighter lift than some might think.

If you are looking to expand your business into a new market segment (like the military) but you don’t have the resources to devote or you just want to keep your team focused on the main business – we can probably help. Just send us email – hello@machinegrowth.co – or visit our website – machinegrowth.co.